Sold

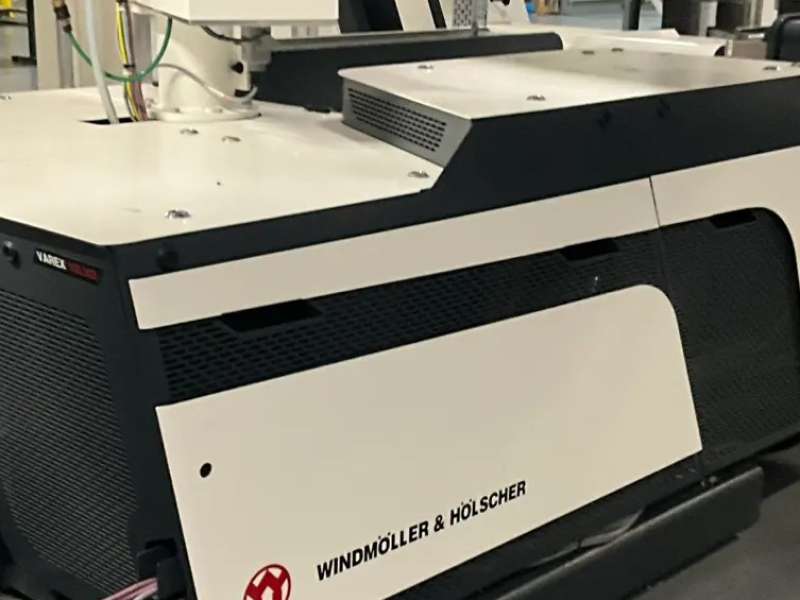

Sold | Machine manufacturer | W&H |

| Model | Varex |

| Year | 2018 |

| Layers | 3 |

| Diameter screw(s) | 70 - 105 - 70 |

| L:D ratio screw(s) | 30D |

| Diameter die | 500 |

| Max. web width | 2600 mm |

| Max. output | 1180kg/h |

| Rewind manufacturer |

W&H Model Filmatic N |

| Type of winding | Double for flat film |

| Materials |

Designed for PLA film(but other materials possible) 9-100 µm |

| Type of dosing unit | Gravimetric |

| IBC | Yes |

| Thickness measurement | Yes |

| Web guide(s) | Yes |

| Corona treater | Yes |

| Inline slitting | Yes, inculding trim retraction system |

| Tower construction included | Yes |

The W&H VAREX line represents the highest standard in blown film extrusion, trusted worldwide for its reliability, versatility, and long-term value. Built by Windmöller & Hölscher, a global leader in extrusion technology, the VAREX system is designed to deliver consistently high film quality across a wide range of applications, from industrial to high-end consumer packaging.

One of the key advantages of the VAREX line is its modular design, allowing it to be easily adapted to meet specific production needs. Whether the focus is on performance, product innovation, or operational efficiency, VAREX offers proven solutions that scale with the demands of the market.

In addition, Windmoller & Holscher places strong emphasis on automation, ease of operation, and process stability. This results in a more efficient production workflow, reduced material waste, and minimal downtime—all critical factors for a competitive and cost-effective operation.

Choosing a VAREX means investing in a robust, future-ready system backed by a company known for exceptional service, technical support, and a commitment to innovation. It's a smart choice for producers who value consistent output, long-term reliability, and the flexibility to meet changing market demands.