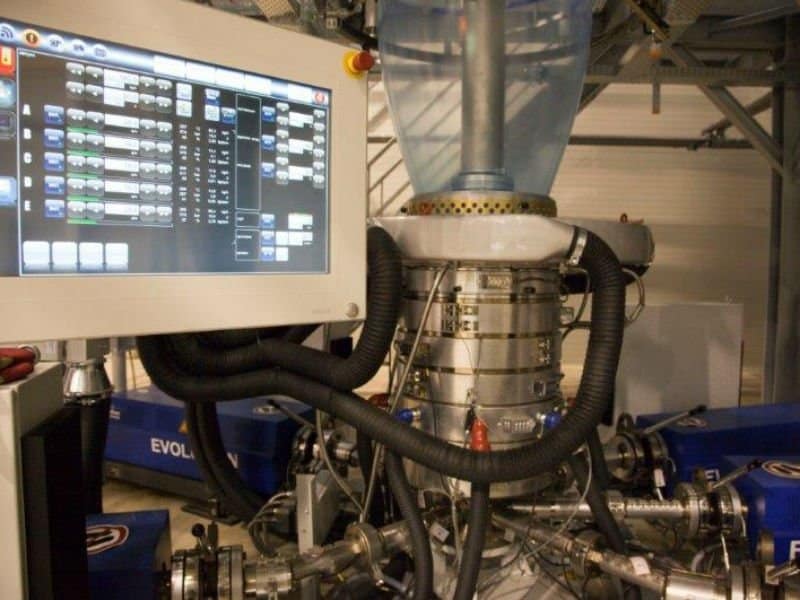

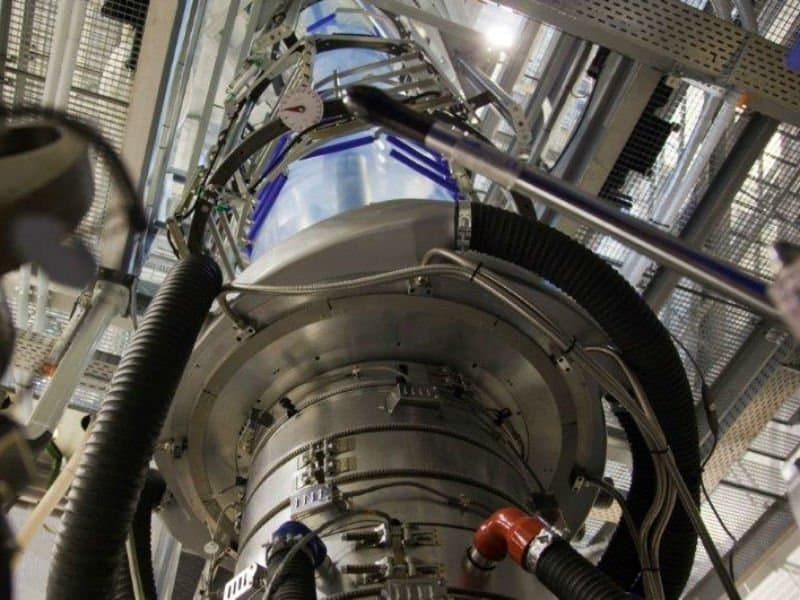

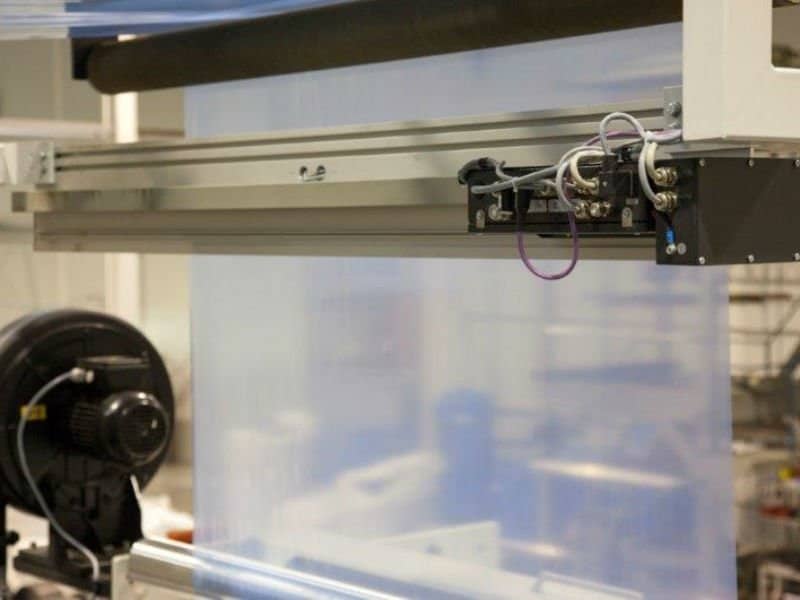

| Machine manufacturer | Reifenhauser |

| Model | Evolution |

| Year | 2012 |

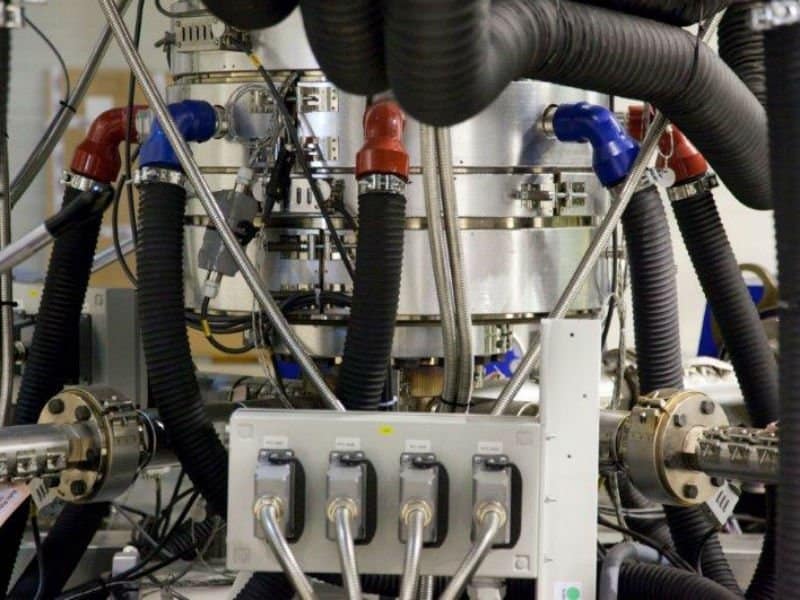

| Layers | 5 |

| Diameter screw(s) | 70 - 50 - 50 - 50 - 70 mm |

| L:D ratio screw(s) | 1:30 |

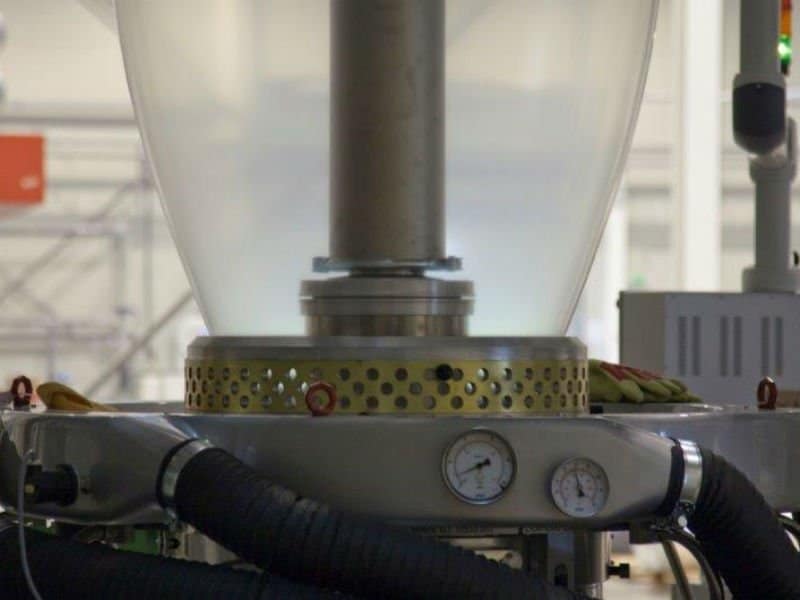

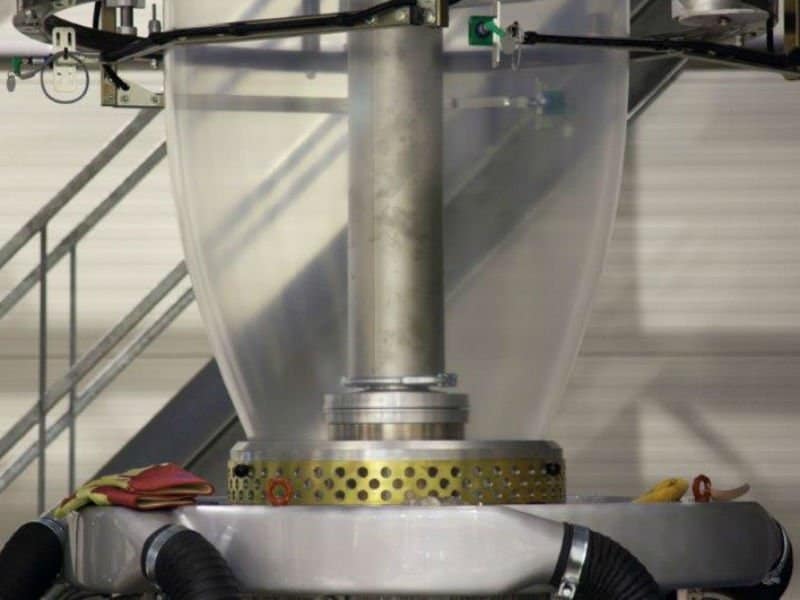

| Diameter die | 300 mm |

| Max. web width | 1600 mm |

| Max. output | 360kg/h |

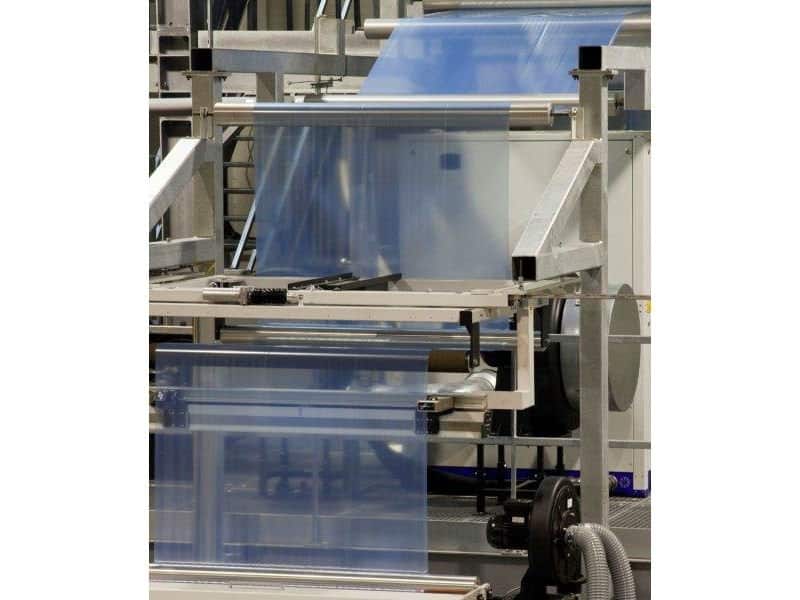

| Rewind manufacturer | Reifenhäuser |

| Type of winding | Double for flat film |

| Materials | LLDPE, LDPE, PP, EVOH, PA |

| Number and size airshafts |

4 x 76 mm 4 x 152 mm |

| Type of screenchanger | Manual |

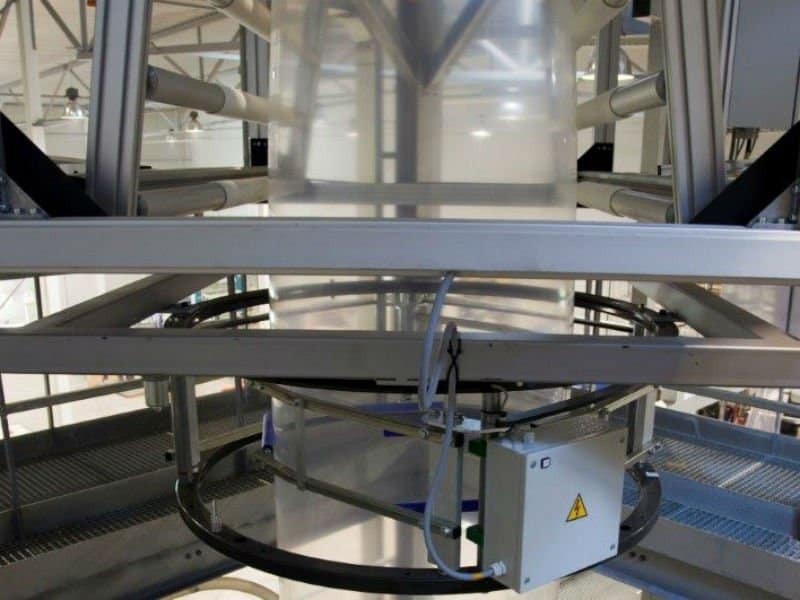

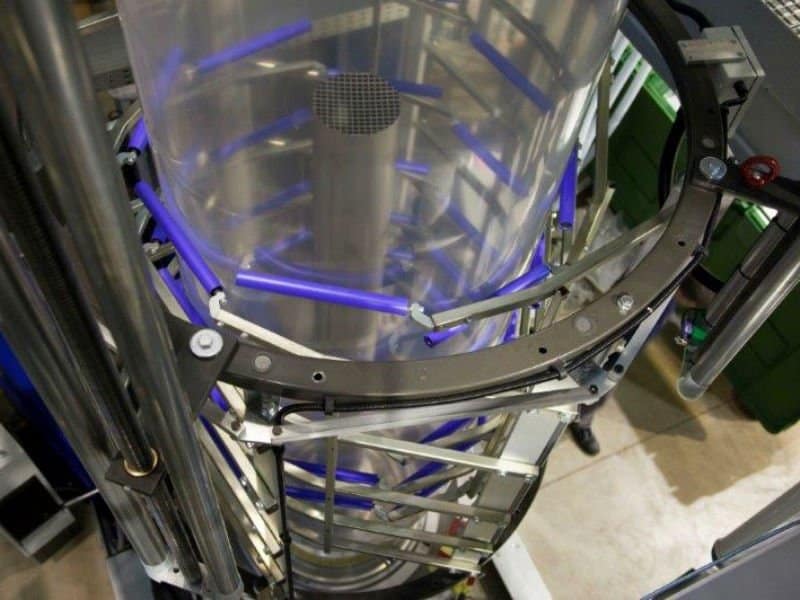

| Rotating/oscillating which part | Take-off |

| Type of dosing unit | Gravimetric |

| IBC | Yes |

| Thickness measurement | Yes |

| Web guide(s) | Yes |

| Inline slitting | Yes |

| Tower construction included | Yes |

| Available from | Now |

| Machine can be seen in production | Yes |

The company Reifenhäuser was founded in 1911 by Anton Reifenhauser. Since its foundation the the company has been 100% family owned and it still is today. The Group employees over 1600 people and is active all over the world. The Group supplies lines and components such as blown film extrusion, cast film extrusion, sheet film extrusion and nonwovens. Reifenhäuser Blown Film develops and manufacturs modular 3 to 12 layer lines with widhts ranging form 1000 to 4300mm.