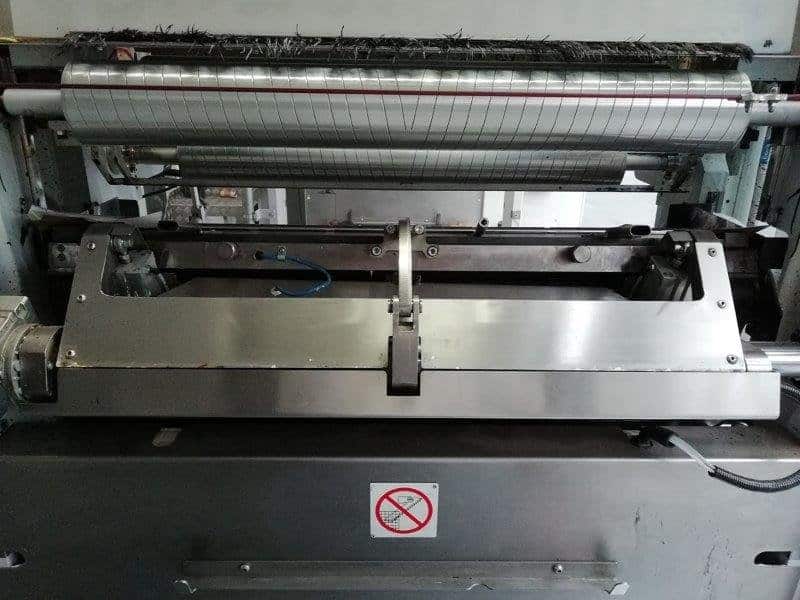

| Machine manufacturer | Rotomec |

| Model | MW80 |

| Year | 2013 |

| Type of inks | Solventbased |

| Number of colours | 9 |

| Max. web width | 850 mm |

| Max. printing width | 850 mm |

| Min. - Max. printing repeat | 825 mm |

| Max. mechanical speed | 350 m/min |

| Materials |

BOPP 15 – 60 mu PET 10 – 60 mu BOPA 15 – 60 mu Alu 20 – 40 mu LDPE 35 – 100 mu Paper 30 – 100 g/m2 |

| Unwind type | Automatic turret |

| Unwind shafted/shaftless | Shafted |

| Max. unwind reel diameter | 1020 mm mm |

| Rewind type | Automatic turret |

| Rewind shafted/shaftless | Shafted |

| Max. rewind reel diameter | 1020 mm mm |

| Number and size airshafts |

4 x 76 mm 4 x 152 mm |

| Drying type | Thermic oil |

| Drying source included | No |

| Extended drying | Yes, 9th station |

| Web guide(s) | Yes |

| Video camera | Yes, Eltromat twin check with 100% inspection |

| Corona treater | Yes, M.E.R.O. |

| Viscosity control | Yes, New Celio |

| Turningcross | Yes, before 9th station |

| Available from | Now |

| Machine can be seen in production | Yes |

Although not producing machines under their own name anymore Rotomec was founded in Italy and has been manufacturing high-quality rotogravure printing presses installed worldwide with satisfied customers. In 2006 Rotomec became part of Bobst Italia Spa, and at the moment, they are well known for their up-to-date and innovative rotogravure printing technology implemented in the different Rotomec machines such as RS 6003, MW 60, MW 80, RS 40000Xi, RS 50002, and new Expert RS6003. The Bobst Rotomec product range established a strong position in the global market because of its state-of-the-art, high productive and user-friendly rotogravure printing machines. Other strong selling points are the high efficiency of the machines and the waste reduction performance which points out a sustainable way of working. With the newly developed Lemanic range and Kochsiek printing machines, characterized by high production quality and reliability, Bobst Rotomec has a firm position in the rotogravure machinery business.