| Machine manufacturer | Nanjiang |

| Model | WFD-430 |

| Year | 2019 |

| Type of bag | Block bottom/SOS bag |

| Min-Max bag width |

220 - 450 mm mm 160 - 430 mm without handle |

| Min. - Max. cut off length |

270 - 520 mm mm 270 - 600 mm without handle |

| Min- Max bottom width | 80 - 200 mm mm |

| Handle unit |

Yes, twisted rope or flat handle Length of twisted rope: 155 - 175mm Diameter of twisted rope: 4 - 6 mm |

| Max. number of cycles (cycles/min) | 110 bags/minute |

| Materials |

Paper 80- 150 gsm 70 - 150 gsm without handle |

| Max. unwind reel diameter | 1200 mm |

| Other information |

Size of flat belt: 15 mm Handle patch length: 190 mm Handle patch width: 35 – 50 mm Handle patch roll diameter: 1000 mm Paper patch roll width: 70 – 100 mm |

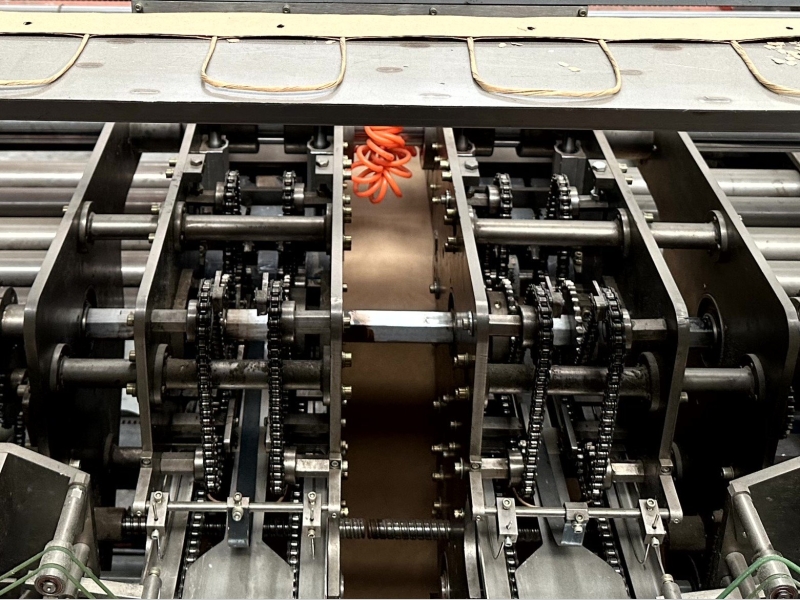

This specialized machine is designed for manufacturing shopping bags, specifically block bottom bags, featuring either twisted rope handles or flat belt handles made from paper. It can utilize either paper rolls or printed paper rolls as its material input. The entire operation of the machine is overseen by a computer central control system with a touch screen interface and servo motor for precise cut-off length control. This machine is capable of producing paper bags in various sizes and can seamlessly attach paper handles inline, eliminating the need for manual intervention. The process includes automatic paper feeding from the roll, tube formation, cut-off, bottom formation, bottom gluing, bag formation, and final bag output. All these steps are executed in a continuous line, making it an efficient solution for the production of twist and flat handle square bottom paper bags. It represents the pinnacle of technology both domestically and internationally.