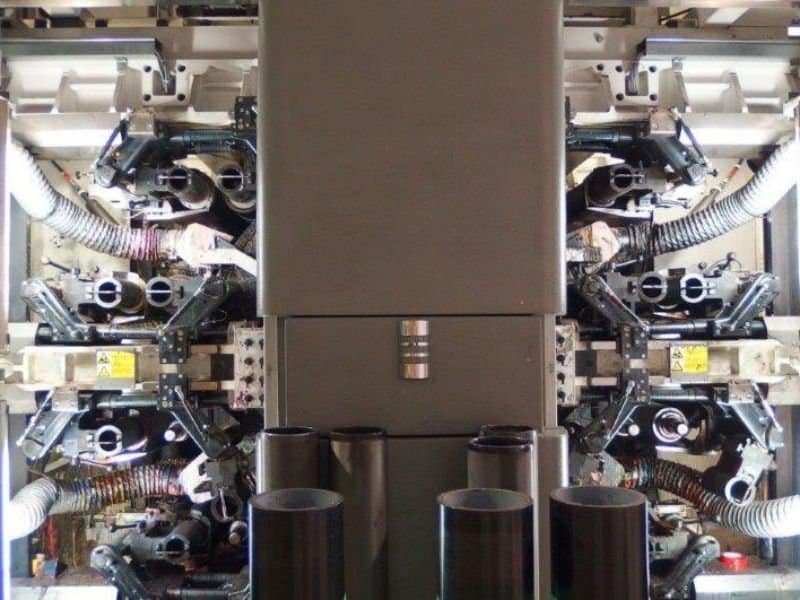

| Machine manufacturer | Soma |

| Model | Flex Midi |

| Year | 2008 |

| Cl or Stack | Cl |

| Geared or Gearless | Gearless |

| Type of inks | Solventbased |

| Number of colours | 8 |

| Max. web width | 1100 mm |

| Max. printing width | 1050 mm |

| Min. - Max. printing repeat | 330 - 800 mm |

| Max. mechanical speed | 450 m/min |

| Materials |

LDPE, PP 20 - 160 micron HDPE, OPP 12 - 100 micron BOPP, PET, OPA 10 - 50 micron Metallized film 10 - 50 micron Laminates 20 - 160 micron paper 25 - 120 g/m2 |

| Unwind type | Automatic turret |

| Unwind shafted/shaftless | Shafted |

| Max. unwind reel diameter | 1000 mm mm |

| Rewind type | Automatic turret |

| Rewind shafted/shaftless | Shafted |

| Max. rewind reel diameter | 1000 mm mm |

| Drying type | Gas |

| Web guide(s) | Yes, E&L |

| Video camera | Yes, BST 3chip digital camera |

| Corona treater | Yes |

| Viscosity control | Yes |

| Number of aniloxes | 25 (see pdf) |

| Number of sleeves | 264 (see pdf) |

| Available from | Now |

| Machine can be seen in production | Yes |

This flexographic printer was build in 2008 and can print up to 8 colours. The web width is 1100 mm and the maximum repeat 850mm. Machine is equipped with fully automatic turret winders. The drying is gas type and machine is equipped with a 3 chip BST camera and corona treater. There are over 250 sleeves with this machine and 25 aniloxes. Speed up to 450 m/min.