Sold machines

Galred has acted as an intermediary in the sales of hundreds of machines in the past few years. Below you can find a selection of these sold machines. Interested in which machines are available for sale at the moment? In our machine list you can find the current offer of used printing machines , bag making machines , extruders , slitters and more. If you are interested in selling one of your own surplus machines you can read more about the sales opportunities or contact us for more information.

Sold

Comexi FL2508 flexo gearless printing press

Year: 2005

Sold

Mamata Vega 800-S sideseal bagmaking machine

Year: 2005

Sold

Titan ER610 slitter rewinder

Year: 2016

Sold

Totani FD3500L

Year: 2007

Sold

Bimec TF-60.2 slitter rewinder

Year: 2017

Sold

Roan RS35-24 pouch bagmaking machine

Year: 2007

Sold

Nordmeccanica Super Simplex solventless laminator

Year: 2014

Sold

Roan RS35-30 pouch bagmaking machine

Year: 2006

Sold

Roan RSU30 pouch bagmaking machine

Year: 2006

Sold

Ashe Sapphire slitter rewinder

Year: 2003

Sold

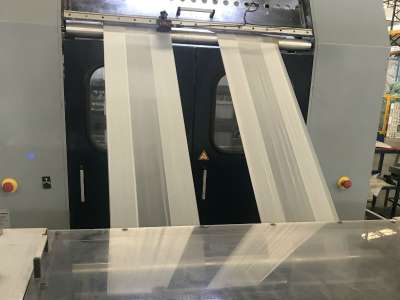

Bobst 20six flexo gearless printing press-2

Year: 2014

Sold

Nordmeccanica Simplex solventless laminator

Year: 1999

Sold

Roan RSU 30-105 pouch bagmaking machine

Year: 2005

Sold

Uteco Izar solventless laminator

Year: 2017

Sold

Atlas CSE620 slitter rewinder

Year: 2011

Sold

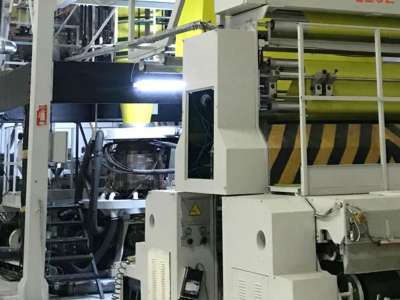

W&H Miraflex flexo gearless printing press

Year: 2015

Sold

Roan RS35 pouch bagmaking machine

Year: 2006

Sold

Titan SR6 slitter rewinder

Year: 2000

Sold

Schiavi Eco Convert solventless laminator

Year: 1998

Sold

Flexotecnica waterbased flexo printing press

Year: 2005

Sold

Nordmeccanica Super Combi 2000 solventless laminator

Year: 2004

Sold

Titan SR6 slitter rewinder

Year: 1996

Sold

Arvor 1182GL bottomseal bagmaking machine

Year: 1985

Sold

F&K 16S flexo gearless printing press

Year: 2005

Sold

F&K 16S flexo gearless printing press

Year: 2004

Sold

Tosa automatic stretch wrapping machine

Year: 1995

Sold

Battenfeld Gloucester cast extrusion line

Year: 2000

Sold

W&H Heliostar rotogravure printing press

Year: 2005

Sold

Gloenco (Gloucester) cast extrusion line

Year: 1986

Sold

Uteco-Usimeca DAS slitter rewinder

Year: 1997

Sold

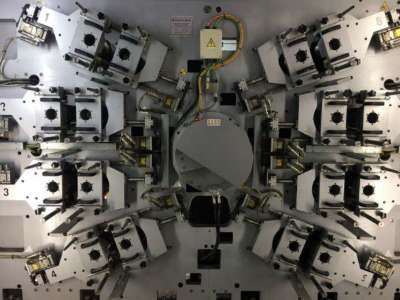

AV Flexologic MOM 1500DD plate mounter

Year: 2012

Sold

Mamata Vega 820 Plus pouch bagmaking machine

Year: 2011

Sold

Erema Intarema 1006 TVEplus recycling line

Year: 2017

Sold

Comexi FW flexo gearless printing press

Year: 2010

Sold

W&H Stellaflex flexo CI printing press

Year: 1997

Sold

Carint Miniflex CX8 flexo CI printing press

Year: 1996

Sold

Gur-Is MS-245 t-shirt bagmaking machine

Year: 2006

Sold

Honsel 326 paper bagmaking machine

Year: 1991

Sold

Gur-Is BSF 950 bottomseal bagmaking machine

Year: 2017

Sold

W&H Soloflex flexo CI printing press

Year: 2001

Sold

Coemter Ter Roll bag on the roll machine

Year: 1994

Sold

Gunter ABW bag on the roll machine

Year: 1981

Sold

Sachsenring 626 W20 on the roll bagmaking machine

Year: 1999

Sold

PCMC Avanti flexo gearless printing press

Year: 2002

Sold

Lemo Intermat loophandle bagmaking machine

Year: 2005

Sold

Flexotecnica FNC 905 flexo CI printing press

Year: 1995

Sold

W&H Polyrex loophandle bagmaking machine

Year: 1998

Sold

Schiavi Sigma flexo gearless printing press

Year: 2002

Sold

FMC M1300 DT on the roll bagmaking machine

Year: 1995

Sold

Comexi Nexus EVO solventless laminator

Year: 2005

Sold

W&H Primaflex flexo gearless printing press

Year: 2007

Sold

Reifenhauser blown film extrusion line

Year: 2010

Sold

Bielloni Telia flexo gearless printing press

Year: 2015

Sold

W&H Soloflex flexo CI printing press

Year: 1997

Sold

Comexi Dual combi laminator

Year: 2017

Sold

Alan Duffy ICS1000 slitter rewinder

Year: 1990

Sold

SML cast extrusion line

Year: 1997

Sold

H&S 1063W wicket bagmaking machine

Year: 1998

Sold

W&H Soloflex flexo CI printing press

Year: 2001

Sold

W&H Filmex cast extrusion line

Year: 2006

Sold

Bimec TCA slitter rewinder

Year: 2005

Sold

Nordmeccanica Simplex solventless laminator

Year: 2004

Sold

W&H Optimex blown film extrusion line

Year: 2011

Sold

Bimec STM slitter rewinder

Year: 2009

Sold

Coemter T-roll bag on the roll machine

Year: 1997

Sold

W&H Polyrex loophandle bagmaking machine

Year: 1997

Sold

Nordson SB2000 hotmelt coater

Year: 1995

Sold

LWKB Elb fa 1600 bottomseal bagmaking machine

Year: 1992

Sold

Bobst SL850 solventless laminator

Year: 2014

Sold

Jiajing JPW hydraulic baler

Year: 2018

Sold

Dolci cast extrusion line

Year: 2013

Sold

Colines cast extrusion line

Year: 2009

Sold

Jagerberg Vari Dur 33-18 slitter rewinder

Year: 1975

Sold

Remak MT6X1200 flexo CI printing press

YearL 2008

Sold

Soma Lamiflex solventless laminator

Year: 2010

Sold

Nordmeccanica Zenit solventbased laminator

Year: 1987

Sold

TItan SR7 slitter rewinder

Year: 2003

Sold

Schiavi Sigma flexo gearless printing press

Year: 2002

Sold

Titan SR8 slitter rewinder

Year: 2008

Sold

Rotomec wax coater

Year: 1976

Sold

Fas Flexuct Fasette C cutting unit

Year: 1998

Sold

W&H Novoflex flexo gearless printing press

Year: 2004

Sold

Sitec SMA 600/1300 slitter rewinder

Year: 1997

Sold

TCE cast extrusion line

Year: 2000

Sold

Reifenhauser blown film extrusion line

Year: 1985

Sold

Helmut Berger M139 die cutter

Year: 2004

Sold

BHS wax laminator/hotmelt coater

Year: 1985

Sold

Füll FS182 ink mixing installation

Year: 2001

Sold

Reifenhauser blown film extrusion line

Year: 1988

Sold

Rotomec Rotopak rotogravure printing press

YearL 1977

Sold

F&K 16S flexo gearless printing press

Year:2000

Sold

Dürr Ecopure RTO unit

Year: 1995

Sold

Kroenert Recco 800 triplex coater/laminator

Year: 2005

Sold

NGR S-Gran recycling line

Year: 2006

Sold

Alan Duffy Eagle DC 650 slitter rewinder

Year: 1989

Sold

Reifenhauser blown film extrusion line

YearL 1998

Sold

Schiavi Sigma4020 flexo printing press

Year: 2003

Sold

F&K 16S flexo gearless printing press

Year: 2000

Sold

W&H Soloflex flexo CI printing press

Year: 1988

Sold

Schiavi Alpha flexo gearless printing press

Year: 2002

Sold

Schiavi EF4040 flexo gearless printing press

Year: 2008

Sold

Uteco Coral flexo CI printing press

Year: 1994

Sold

Uteco Emerald flexo gearless printing press

Year: 2003

Sold

F&K 34DF flexo CI printing press

Year: 1995

Sold

Carint SLP flexo CI printing press

Year: 2005

Sold

Karlville KJ-SUP-400 pouch bagmaking machine

Year: 2017

Sold

Hemmingstone HM-1000MSR bag on the roll machine

Year: 2003

Sold

Hemmingstone HM-1000 drawtape bagmaking machine

Year: 2012

Sold

W&H Starflex flexo CI printing press

Year: 1997

Sold

Roll-o-Matic Delta 860 bagmaking machine

Year: 2008

Sold

W&H Starflex flexo CI printing press

Year: 1993

Sold

Arvor Eco Classic bottomseal bagmaking machine

Year: 2011

Sold

Tiquattro Elene flexo CI printing press

Year: 2004

Sold

Carint Gemini flexo CI printing press

YearL 1987

Sold

Ashe Sapphire S slitter rewinder

Year: 2006

Sold

Ashe Diamond slitter rewinder

Year: 2015

Sold

Wickeltechnick WFZ slitter rewinder

Year: 2000

Sold

Ashe Sapphire S slitter rewinder

Year: 2005

Sold

Uteco Mira solventless laminator

Year: 2015

Sold

Schiavi Ecoflex solventbased laminator

Year: 2010

Sold

Roll-o-Matic Delta 900 t-shirt bagmaking machine

Year: 2015

Sold

TMB Speedflex inline flexo printing press

Year: 2010

Sold

Schiavi Ecoflex solventless laminator

Year: 2000

Sold

Lemo Intermat wicket bagmaking machine

Year: 1994

Sold

Weyhmuller DSV70 ice cone wrap machine-1

Year: 2004

Sold

Soma Premia flexo gearless printing press

Year: 2014

Sold

Weyhmuller DSV70 ice cone wrap machine

Year: 2008

Sold

Uteco Emerald flexo gearless printing press

Year: 2010

Sold

Bimec STM-43 slitter rewinder

Year: 2012

Sold

Barmag blown film extrusion line

Year: 1996

Sold

Acom Variant 12 solventbased laminator

Year: 2004

Sold

Bimec STM-50 slitter rewinder

Year: 2016

Sold

Comexi FS-1500 flexo CI printing press

Year: 1996

Sold

Rotomec Valmet rotogravure printing press

Year: 2003

Sold

Polytype Bangerter alu coater

Year: 1970

Sold

Barmag blown film extrusion line

Year: 1989

Sold

Uteco Quartz inline flexo stack gearless printing press

Year: 2014

Sold

Olivini flexo gearless stack printing press

Year: 2001

Sold

Comexi S-Turret slitter rewinder

Year: 2013

Sold

Cerutti R940 rotogravure printing press

Year: 1997

Sold

Cobden Chadwick No2 paper bagmaking machine

Year: 1970

Sold

Megtec VOC RTO unit

Year: 2010

Sold

Macro Engineering blown film extrusion line

Year: 2013

Sold

Uteco Topax 608 flexo gearless printing press

Year: 2014

Sold

Andreotti Rotostar rotogravure printing press

Year: 1993

Sold

Nordmeccanica Super Simplex solventless laminator

Year: 1995

Sold

Bielloni B64 slitter rewinder

Year: 1990

Sold

Beasly&French No 2 paper bagmaking machine

Year: 1970

Sold

Kampf unwinders

Year: 1998

Sold

Beasly&French No 3 paper bagmaking machine

Year: 1970

Sold

Comexi S-Turret slitter rewinder

Year: 2013

Sold

W&H Varex blown film extrusion line

Year: 2008

Sold

Comexi SLC-120 solventless laminator

Year: 2001

Sold

Schiavi Padane wax coating line

Year: 2010

Sold

CMF Mirage flexo CI printing press

Year: 1988

Sold

H&S 2750W wicket bagmaking machine

Year: 1994

Sold

Eme Engel slitter rewinder

Year: 1995

Sold

Pratti Vegaplus label puncher

Year: 2014

Sold

Uteco Onyx flexo gearless printing press

Year: 2007

Sold

Raantec PlateExact 400 plate mounter

Year: 2013

Sold

Megtec CC60-C5 RTO unit

Year: 2009

Sold

Macchi blown film extrusion line

Year: 2006

Sold

Uteco Topaz 808 flexo gearless printing press

Year: 2012

Sold

Arvor Alpha 1499 bottomseal bagmaking machine

Year: 2002

Sold

Cerutti R38 rotogravure printing press

Year: 1976

Sold

Titan SR6 slitter rewinder

Year: 1995

Sold

F&K 34DF flexo CI printing press

Year: 1992

Sold

Atlas Copco GA26VSD compressor

Year: 2015

Sold

Schiavi Roto Cadet S rotogravure printing press

Year; 1995

Sold

Alphasonic ALP1630 ultrasonic anilox cleaner

Year: 2016

Sold

Uteco Rainbow solventless laminator

Year: 2012

Sold

Comexi Proslit Compack 2 slitter rewinder

Year: 2010

Sold

Lemo IV 1100 TU-ST diaper bagmaking machine

Year: 1999

Sold

CMR Flexporint 420-8GL flexo label printing press

Year: 2007

Sold

Sys Tec Star-HD sleeves 1300 plate mounter

Year: 2015

Sold

FAS CT500 cutting unit for T-shirt and top wave bags

Year: 2012

Sold

Uteco Zeus 188 slitter rewinder

Year: 2012

Sold

Polytype KST6630 solventless laminator

Year: 1994

Sold

MAM blown film extrusion line

Year: 1997

Sold

Sys Tec VP-HD 1200 plate mounter

Year: 2011

Sold

Sitec SMA 600/1300 slitter rewinder

Year: 1996

Sold

FAS CT500 cutting unit for T-shirt and top wave bags

Year: 2012

Sold

Hobema 14C napkin machine

Year: 1976

Sold

Nilpeter 2400 flexo label printing press

Year: 1999

Sold

Rotomec 3000-3R rotogravure printing press

Year: 1998

Sold

W&H Triumph 5 paper bagmaking machine

Year: 1972>

Sold

Flexotecnica Tachys flexo CI printing press

Year: 1998

Sold

Comexi FI flexo gearless printing press

Year: 2006

Sold

W&H Miraflex flexo gearless printing press

Year: 2011

Sold

W&H Primaflex flexo gearless printing press

Year: 2006

Sold

Comexi FW flexo gearless printing press

Year: 2009

Sold

W&H Stellaflex flexo CI printing press

Year: 1996

Sold

W&H Stellaflex flexo CI printing press

Year: 1996

Sold

W&H Astraflex flexo CI printing press

Year: 2000

Sold

W&H Soloflex flexo CI printing press

Year: 1995

Sold

Bobst 20six flexo gearless printing press-1

Year: 2015

Sold

W&H Miraflex flexo gearless printing press

Year: 2015

Sold

Comexi FW flexo gearless printing press

Year: 2002

Sold

Comexi FL flexo gearless printing press

Year: 2003

Sold

Ofem Appia GL808 flexo gearless printing press

Year: 2007

Sold

Somo Midi II flexo gearless printing press

YearL 2011

Sold

BHS Flexoline Vario flexo gearless printing press

Year: 2003

Sold

Flexotecnica Policroma flexo CI printing press

Year: 2007

Sold

Lemo Capmat 850 courier bagmaking machine

Year: 2012

Sold

F&K 16S flexo gearless printing press

Year: 2001

Sold

Flexotecnica Chronos flexo gearless printing press

Year: 2004

Sold

Lemo 850DKT patch handle bagmaking machine

Year: 1999

Sold

W&H Polyrex loophandle bagmaking machine

Year: 2002

Sold

Flexotecnica 806 flexo CI printing press

Year: 1984

Sold

Lemo Intermat wicket bagmaking machine

Year: 1994

Sold

Comexi FW flexo gearless printing press

Year: 2011

Sold

W&H Stellaflex flexo CI printing press

Year: 1997

Sold

Flexotecnica FX8 waterbased flexo gearless printing press

Year: 2010

Sold

Avita AVP courier bagmaking machine

Year: 2013

Sold

W&H Starflex flexo CI printing press

Year: 1993

Sold

FMC 105 courier bagmaking machine

Year: 2010

Sold

Bone Craven blown film extrusion line

Year: 1974

Sold

W&H Starflex flexo CI printing press

Year: 1994

Sold

Uteco Onyx flexo gearless printing press

Year: 2012

Sold

W&H Matador 26 paper bagmaking machine

Year: 1975

Sold

Comexi FP flexo CI printing press

Year: 1997

Sold

Stiegler wicket bagmaking machine

Year: 2000

Sold

Bobst Rotoextruder 700 extrusion laminating line

Year: 2015

Sold

Comexi FW flexo gearless printing press

Year: 2004

Sold

Bielloni Taglierina slitter rewinder

Year: 2007

Sold

F&K vulcanising unit

Year: 1962

Sold

Uteco-Usimeca LMA slitter rewinder

Year: 1995

Sold

Reifenhauser blown film extrusion line

Year: 1992

Sold

F&K 16S flexo gearless printing press

Year: 2002

Sold

W&H Primaflex flexo gearless printing press

Year: 2005

Sold

Cerutti R940 rotogravure printing press

Year: 2002

Sold

Lemo bottomseal bagmaking machine

Year: 2016

Sold

Reifenhauser blown film extrusion line

Year: 1999

Sold

Soma Z3540C slitter rewinder

Year: 2000

Sold

Polytype wax coating line

Year: 1970

Sold

Leybold lab high vacuum coater

Year: 2007

Sold

Reifenhauser blown film extrusion line

Year: 1991

Sold

Kampf FK2-2 slitter rewinder

Year: 1965

Sold

Bobst 20six waterbased flexo gearless printing press

Year: 2012

Sold

H&S 5750W wicket bagmaking machine

Year: 2010

Sold

Nordmeccanica Triplex SL One Shot solventless laminator

Year: 2009

Sold

Z-rite Exact Spectrometer

Year: 2014

Sold

OMM AZ2 UT 3000 wide web slitter rewinder

Year: 1988

Sold

Nordmeccanica Super Simplex solventless laminator

Year: 2002

Sold

Harro Höfliger medical bagmaking machine

Year: 2013

Sold

Nordmeccanica Zenit solventbased laminator

Year: 1988

Sold

AV Flexologic plate mounter

Year: 1995

Sold

Waterline pouch bagmaking machine

Year: 1996

Sold

Reifenhauser blown film extrusion line

Year: 1983

Sold

Uteco SH 350 rotogravure printing press

Year: 2014

Sold

Titan SR6 slitter rewinder

Year: 1996

Sold

Comet S674 blown film extrusion line

Year: 2000

Sold

Comexi Proslit Duo 2 slitter rewinder

Year: 2007

Sold

Comexi Dual combi laminator

Year: 2011

Sold

Cerutti R940 rotogravure printing press

Year: 1997

Sold

Vela RB-600 sleeve maker

Year: 2007

Sold

Elba BM11BW13 bottomseal bagmaking machine

Year: 2015

Sold

Comet S674 blown film extrusion line

Year: 2005

Sold

Nordmeccanica Super Combi laminator

Year: 2005

Sold

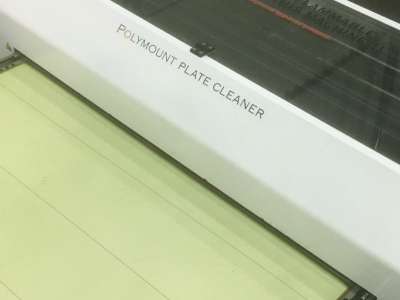

Polymount L-2 plate cleaner

Year: 2012

Sold

W&H Astraflex flexo CI printing press

Year: 2001

Sold

W&H solventless laminator

Year: 1991

Sold

Comet S674 blown film extrusion line

Year: 1998

Sold

Eme FXCM flexo stack printing press

Year: 1998

Sold

Renzmann anilox washing machine

Year: 2007

Sold

Euromac TB-510 slitter rewinder

Year: 1986

Sold

BHS FS-650 flexo label printing press

Year: 1999

Sold

Lemo Intermat 1100 hygiene bagmaking machine

Year: 1994

Sold

Erema 756 TE-SW recycling line

Year: 2008

Sold

Flexowash SL6 sleeve washer

Year: 2009

Sold

Nilpeter FA4 flexo label printing press

Year: 2007

Sold

Bieffebi Mirage 336-180C plate mounter

Year: 1996

Sold

Comet S674 blown film extrusion line

Year: 1992

Sold

Euromac TB-506 slitter rewinder

Year: 1999

Sold

Renzmann Roto-400 destillation unit

Year: 2004

Sold

Schiavi Eco Convert solventless laminator

Year: 1998

Sold

Flexotecnica Ekaton inline flexo stack printing press

Year: 1990

Sold

W&H Novoflex XS flexo gearless printing press

Year: 2005

Sold

W&H Soloflex flexo CI printing press

Year: 1994

Sold

Comexi FPLUS flexo gearless printing press

Year: 2012

Sold

PCMC Infiniti flexo gearless printing press

Year: 2000

Sold

W&H Soloflex flexo CI printing press

Year: 2004

Sold

W&H Soloflex flexo CI printing press

Year: 2002

Sold

F&K 31DF flexo stack printing press

Year: 1971

Sold

F&K 34DF flexo CI printing press

Year: 1990

Sold

W&H Novoflex flexo gearless printing press

Year: 2000

Sold

W&H QMS flexo stack printing press

Year: 1970

Sold

Eme FXCM flexo stack printing press

Year: 2002

Sold

Comexi FP flexo CI printing press

Year: 2000

Sold

Comexi FX flexo CI printing press

Year: 1996

Sold

Comexi FB flexo gearless printing press

Year: 2004

Sold

W&H Soloflex flexo CI printing press

Year: 1999

Sold

Bonardi Ofelia flexo stack printing press

Year: 2003

Sold

W&H TR1 SOS paper bagmaking machine

Year: 1972

Sold

Coemter Ter Roll bag on the roll machine

Year: 1998

Sold

GN 26P security pouch bagmaking machine

Year: 2003

Sold

Lee Yuen inline flexo stack printing press

Year: 2013

Sold

Hettler FK2000 cottonstring bagmaking machine

Year: 2010

Sold

Some Mini 8 flexo gearless printing press

Year: 2006

Sold

Totani BH-60V pouch bagmaking machine

Year: 1999

Sold

Lemo Intermat wicket bagmaking machine

Year: 2000

Sold

F&K 16S flexo gearless printing press

Year: 2001

Sold

Flexotecnica 10NG flexo gearless printing press

Year: 2009

Sold

FMC 2750W wicket bagmaking machine

Year: 1992

Sold

Totani BH-600 BL pouch bagmaking machine

Year: 1986

Sold

Lemo Varitronic 1100 drawtape bagmaking machine

Year: 1999

Sold

MAF Galaxi flexo CI printing press

Year: 1993

Sold

Euroexma lab blown film extrusion line

Year: 2015

Sold

MAF Galaxi flexo CI printing press

Year: 1989

Sold

W&H AD Convertex blockbottom/valve bagmaking machine

Year: 2000

Sold

Lemo S850 glue patch bagmaking machine

Year: 2002

Sold

W&H Olympia 900 flexo stack printing press

Year: 1977

Sold

Roll-o-Matic 605 t-shirt bagmaking machine

Year: 2002

Sold

W&H Filmex cast extrusion line

Year: 2011

Sold

Rotomec extrusion laminating line

Year: 1975

Sold

W&H Varex blown film extrusion line

Year: 1998

Sold

Chadwick flexo CI printing press

Year: 1988

Sold

Waterline Ritebag 600 pouch bagmaking machine

Year: 2013

Sold

Lemo drawtape bagmaking machine

Year: 2002

Sold

F&K 34DF flexo CI printing press

Year: 2000

Sold

Formac Mini 20 lab blown film extrusion line

Year: 1999

Sold

Yei blown film extrusion line

Year: 1998

Sold

De Bernardi 100E pouch bagmaking machine

Year: 2003

Sold

Uteco Onyx 876 flexo gearless printing press

Year: 2005

Sold

W&H Rotalux bottomseal bagmaking machine

Year: 1989

Sold

Carint Cyberflex flexo gearless printing press

Year: 2004

Sold

Yei blown film extrusion line

Year: 2000

Sold

F&K 10DF flexo CI printing press

Year: 1996

Sold

Gunter bottomseal bagmaking machine

Year: 2002

Sold

Curioni Sun 540 paper bagmaking machine

Year: 1998

Sold

Reifenhauser blown film extrusion line

Year: 2001

Sold

Fin Kon wicket bagmaking machine

Year: 1998

Sold

Bielloni Theorema flexo gearless printing press

Year: 2003

Sold

Reifenhauser blown film extrusion line

Year: 2001

Sold

W&H AMD flexo inline stack printing press

Year: :1975

Sold

Holweg RS26 paper bagmaking machine

Year: 1997

Sold

W&H Olympia 850 flexo stack printing press

Year: 1980

Sold

Reifenhauser blown film extrusion line

Year: 2001

Sold

Coemter Ter Roll bag on the roll machine

Year: 1999

Sold

W&H Convertronic pouch bagmaking machine

Year: 1995

Sold

Schiavi Sirio flexo CI printing press

Year: 2001

Sold

Flexotecnica flexo CI printing press

Year: 1996

Sold

F&K 34DF flexo CI printing press

Year: 1982

Sold

Alpine blown film extrusion line

Year: 1993

Sold

Ashe Solitaire slitter rewinder

Year: 2007

Sold

Carint Skorpion flexo CI printing press

Year: 2011

Sold

Ashe Solitaire slitter rewinder

Year: 2002

Sold

Erwepa cast extrusion line

Year: 2000

Sold

Metecor flexo stack printing press

Year: 2005

Sold

Ahlstrom Syromat jumbo slitter rewinder

Year: 1990

Sold

Renova cottonstring bagmaking machine

Year: 1997

Sold

Macchi blown film extrusion line

Year: 2002

Sold

Coemter t-shirt bagmaking machine

Year: 1994

Sold

Galileo MSR25 slitter rewinder

Year: 2003

Sold

Hanyoung extrusion coating line

Year: 2001

Sold

W&H Olympia 746 flexo CI printing press

Year: 1989

Sold

PSA Allslit slitter rewinder

Year: 2009

Sold

Wolf sheeter with inline printing unit

Year: 1980

Sold

Hanyoung extrusion coating line

Year: 2001

Sold

W&H Starflex flexo CI printing press

Year: 1992

Sold

W&H Matador S1 paper bagmaking machine

Year: 1996

Sold

Lemo Rollomat bag on the roll bagmaking machine

Year: 1996

Sold

Addex blown film extrusion line

Year: 2004

Sold

Carint Gemini flexo CI printing press

Year: 1991

Sold

Nordmeccanica Super Combi laminator

Year: 2014

Sold

Comexi Nexus Dual combi laminator

Year: 2008

Sold

H&S 4750W wicket bagmaking machine

Year: 2001

Sold

Macchi blown film extrusion line

Year: 1996

Sold

Kampf Conslit 10/60 slitter rewinder

Year: 1996

Sold

Flexotecnica NG8 flexo gearless printing press

Year: 2009

Sold

Galileo Mega 2410A metalizer

Year: 1998

Sold

BAT hydraulic compactors

Year: 2003

Sold

W&H Olympia flexo CI printing press

YearL 1980

Sold

Lemo Intermat bottomseal bagmaking machine

Year: 1986

Sold

Mix Master ink blending system

Year: 2001

Sold

H&S MS1000 sideseal bagmaking machine

Year: 2002

Sold

Pro Doing slitter rewinder

Year: 2005

Sold

Fong Kee cast extrusion line

Year: 2002

Sold

Flexowash FW3000 anilox cleaner

Year: 2003

Sold

Ofem Selenia solventless laminator

Year: 2002

Sold

Bielloni Gloria flexo CI printing press

Year: 1996

Sold

H&S MS750 sideseal bagmaking machine

Year: 2005

Sold

Delta Graphic slitter rewinder

Year: 1998

Sold

Imaje Jaime 1000 inkjet printers

Year: 2006

Sold

Reifenhauser blown film extrusion line

Year: 1996

Sold

W&H Soloflex flexo CI printing press

Year: 1998

Sold

Pagendarm Lamicoater

Year: 1984

Sold

Arvor unwinder

Year: 1997

Sold

W&H Soloflex flexo CI printing press

Year: 1999

Sold

Uteco-Usimeca slitter rewinder

Year: 1996

Sold

Lemo Intermat loophandle bagmaking machine

Year: 2004

Sold

Comexi CL 1300 solventless laminator

Year: 2002

Sold

NM PA-100 automatic core cutter

Year: 1999

Sold

FAS UWB unwinder

Year: 2006

Sold

F&K 14DF flexo CI printing press

Year: 1983

Sold

Holweg Multiplex combi laminator

Year: 1976

Sold

Lemo Intermat wicket bagmaking machine

Year: 1995

Sold

Titan slitter rewinder

Year: 1999

Sold

Holweg sheeter

Year: 1985

Sold

Barmag monofilament extrusion line

Year: 2008

Sold

SVT drawtape unit

Year: 2007

Sold

Fimap ultrasonic anilox cleaner

Year: 2003

Sold

Comexi FP flexo CI printing press

Year: 1998

Sold

Colombo M139 embosser

Year: 2005

Sold

Cerutti R940 rotogravure printing press

Year: 1993

Sold

Schiavi Easy slit slitter rewinder

Year: 1998

Sold

Lemo Intermat DKT bagmaking machine

Year; 1999

Sold

W&H Stellaflex flexo CI printing press

Year: 1997

Sold

Spag BAC800 slitter rewinder

Year: :1996

Sold

Black Clawson cast extrusion line

Year: 1998

Sold

Schiavi Eco Convert Junior solventless laminator

Year; 1998

Sold

Rotomec Rotopak rotogravure printing press

Year: 1989

Sold

Schiavi Eco Convert Junior solventless laminator

Year: 2002

Sold

Wolf sheeter

Year: 1985

Sold

W&H Stellaflex flexo CI printing press

Year: 1997

Sold

Saldoflex t-shirt bagmaking machine

Year: 2008

Sold

Bimec SMT slitter rewinder

Year: 2009

Sold

Renzmann Roto-140 destillation unit

Year: 2000

Sold

Stiegler wicket bagmaking machine

Year: 2000

Sold

Colines cast extrusion line

Year: 1994

Sold

Manzoni flexo stack printing press

Year: 1998

Sold

Polytech rotogravure printing press

Year: 2004

Sold

W&H Starflex flexo CI printing press

Year: 1990

Sold

Solutex destillation unit

Year: 2009

Sold

Reeco-Stroem after burner

Year: 1997

Sold

Dolci blown film extrusion line

Year: 2004

Sold

Comexi Proslit slitter rewinder

Year: 2008

Sold

Andriotti Rotostar solventbased laminator

Year: 1985

Sold

Erwepa extrusion laminating/coating line

Year: 2012

Sold

Cerutti 18R rotogravure printing press

Year: 1975

Sold

Plast-control K400U air ring

Year: 2006

Sold

Elwa bottomseal bagmaking machine

Year: 1993

Sold

General EHF4 metalizer

Year: 2000

Sold

Engin Plast trim granulator

Year: 1995

Sold

Flexotecnica Prisma flexo CI printing press

Year: 1998

Sold

Schiavi Easy Slit slitter rewinder

Year: 1988

Sold

W&H Heliostar coater

Year: 1995

Sold

Dolci blown film extrusion line

Year: 1980

Sold

Cerutti rotogravure printing press

Year: 1989

Sold

Nishibe SBM-600 pouch bagmaking machine

Year: 2005

Sold

Nordmeccanica Simplex combi laminator

Year: 1996

Sold

Bieffebi Omnia 335 plate mounter

Year: 2006

Sold

Horstmann roll carts for recycling lines

Year: 2000

Sold

Renzmann DW100 destillation unit

Year: 1997

Sold

Fong Kee cast extrusion line

Year: 1998

Sold

W&H Rotiflex flexo/roto printing press

Year: 1974

Sold

Stiegler drawtape bagmaking machine

Year: 1999

Sold

Lombardi Lexus 450 flexo label printing press

Year: 2010

Sold

SRS 410 slitter rewinder

Year: 2015

Sold

Rotogravure cylinders

Year: 1990

Sold

CDM ES50 recycling line

Year: 2006

Sold

Giave Titania rotogravure printing press

Year: 1994

Sold

Printex bottomseal bagmaking machine

Year: 1974

Sold

Heaford Cobra plate mounter

Year: 2012

Sold

Schiavi Polaris flexo CI printing press

Year: 1998

Sold

Cosmoplastik solventbased laminator

Year: 1994

Sold

Flexo Wash TK200WR parts washer-1

Year: 2005

Sold

Uteco-Usimeca LMA slitter rewinder

Year: 1995

Sold

Omet flexo label printing press

Year: 2009

Sold

Rotomec Valmet rotogravure printing press

Year: 1998

Sold

Macchi blown film extrusion line

Year: 2002

Sold

Bobst 20six flexo gearless printing press

Year: 2013

Sold

Polymount plate cleaner

Year: 2008

Sold

DCM Laminawax wax coater/laminator

Year: 2007

Sold

Flexo Wash TK200WR parts washer

Year: 2002

Sold

Munchy P100 recycling line

YearL 1994

Sold

Kiefel blown film extrusion line

Year: 2006

Sold

Entry tight 660 solventless laminator

Year: 2008

Sold

Dolci cast extrusion line

Year: 1993

Sold

AGFA Avantra image setter

Year: 1999

Sold

Uteco-Usimeca DAB slitter rewinder

Year: 1999

Sold

BHS flexo label printing press

Year: 1983

Sold

Starlinger Recostar 125 recycling line

Year: 2004

Sold

Cerutti rotogravure printing press

Year: 1971