| Machine manufacturer | MAF |

| Model | Antares |

| Year | 1995 |

| Cl or Stack | Cl |

| Geared or Gearless | Geared |

| Type of inks | Solventbased |

| Number of colours | 6 |

| Max. web width | 850 mm |

| Max. printing width | 800 mm |

| Min. - Max. printing repeat | 300 - 590 mm |

| Max. mechanical speed | 150 m/min |

| Unwind type | Double |

| Unwind shafted/shaftless | Shafted |

| Max. unwind reel diameter | 800 mm |

| Rewind type | Double |

| Rewind shafted/shaftless | Shafted |

| Max. rewind reel diameter | 800 mm |

| Drying type | Electric |

| Web guide(s) | Yes |

| Video camera | Yes |

| Inline slitting | Yes |

| Number of aniloxes | 7 (120 - 280 l/cm) |

| Number of sleeves | 42 (see pdf) |

| Number of printing cylinders | 48 (see pdf) |

| Number of gears | 108 (see pdf) |

| Special characteristics | Accurate tension control for LLDPE or PVDS stretch foil |

| Available from | Now |

| Machine can be seen in production | Yes |

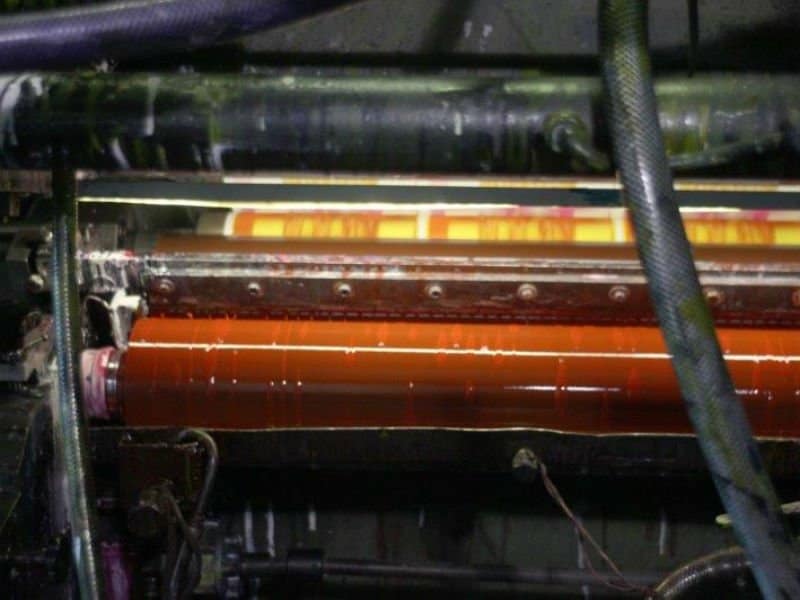

Very attractive price.This flexographic printer has 6 printing decks and can print on a width of 800 mm. Double winders and inline slitting to create smaller reels. Many cylinders, sleeves and gears attached. Can work with very fine tension to allow LLDPE or stretch film printing. BST camera installed on the machine.