Проданные машины

За последние годы компания Galred выступила в качестве посредника при продаже сотен станков. Ниже представлена подборка этих проданных машин. Интересно узнать, какие машины доступны для продажи прямо сейчас? В нашем список машин вы можете найти наш текущий выбор подержанных печатных машин, машин для производства пакетов, экструдеров, резательных машин и многого другого. Если вы заинтересованы в продаже одной из ваших собственных избыточных машин, вы можете прочитать больше о возможностях продажи или связаться с нами для получения дополнительной информации.

Продано

Comexi FL2508 flexo gearless printing press

Year: 2005

Продано

Mamata Vega 800-S sideseal bagmaking machine

Year: 2005

Продано

Titan ER610 slitter rewinder

Year: 2016

Продано

Totani FD3500L

Year: 2007

Продано

Bimec TF-60.2 slitter rewinder

Year: 2017

Продано

Roan RS35-24 pouch bagmaking machine

Year: 2007

Продано

Nordmeccanica Super Simplex solventless laminator

Year: 2014

Продано

Roan RS35-30 pouch bagmaking machine

Year: 2006

Продано

Roan RSU30 pouch bagmaking machine

Year: 2006

Продано

Ashe Sapphire slitter rewinder

Year: 2003

Продано

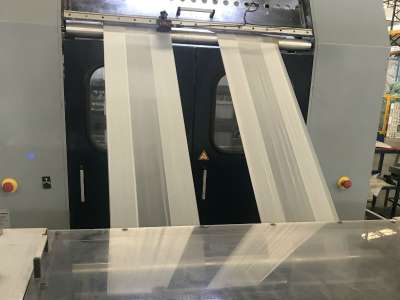

Bobst 20six flexo gearless printing press-2

Year: 2014

Продано

Nordmeccanica Simplex solventless laminator

Year: 1999

Продано

Roan RSU 30-105 pouch bagmaking machine

Year: 2005

Продано

Uteco Izar solventless laminator

Year: 2017

Продано

Atlas CSE620 slitter rewinder

Year: 2011

Продано

W&H Miraflex flexo gearless printing press

Year: 2015

Продано

Roan RS35 pouch bagmaking machine

Year: 2006

Продано

Titan SR6 slitter rewinder

Year: 2000

Продано

Schiavi Eco Convert solventless laminator

Year: 1998

Продано

Flexotecnica waterbased flexo printing press

Year: 2005

Продано

Nordmeccanica Super Combi 2000 solventless laminator

Year: 2004

Продано

Titan SR6 slitter rewinder

Year: 1996

Продано

Arvor 1182GL bottomseal bagmaking machine

Year: 1985

Продано

F&K 16S flexo gearless printing press

Year: 2005

Продано

F&K 16S flexo gearless printing press

Year: 2004

Продано

Tosa automatic stretch wrapping machine

Year: 1995

Продано

Battenfeld Gloucester cast extrusion line

Year: 2000

Продано

W&H Heliostar rotogravure printing press

Year: 2005

Продано

Gloenco (Gloucester) cast extrusion line

Year: 1986

Продано

Uteco-Usimeca DAS slitter rewinder

Year: 1997

Продано

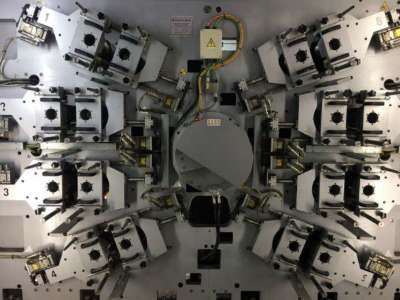

AV Flexologic MOM 1500DD plate mounter

Year: 2012

Продано

Mamata Vega 820 Plus pouch bagmaking machine

Year: 2011

Продано

Erema Intarema 1006 TVEplus recycling line

Year: 2017

Продано

Comexi FW flexo gearless printing press

Year: 2010

Продано

W&H Stellaflex flexo CI printing press

Year: 1997

Продано

Carint Miniflex CX8 flexo CI printing press

Year: 1996

Продано

Gur-Is MS-245 t-shirt bagmaking machine

Year: 2006

Продано

Honsel 326 paper bagmaking machine

Year: 1991

Продано

Gur-Is BSF 950 bottomseal bagmaking machine

Year: 2017

Продано

W&H Soloflex flexo CI printing press

Year: 2001

Продано

Coemter Ter Roll bag on the roll machine

Year: 1994

Продано

Gunter ABW bag on the roll machine

Year: 1981

Продано

Sachsenring 626 W20 on the roll bagmaking machine

Year: 1999

Продано

PCMC Avanti flexo gearless printing press

Year: 2002

Продано

Lemo Intermat loophandle bagmaking machine

Year: 2005

Продано

Flexotecnica FNC 905 flexo CI printing press

Year: 1995

Продано

W&H Polyrex loophandle bagmaking machine

Year: 1998

Продано

Schiavi Sigma flexo gearless printing press

Year: 2002

Продано

FMC M1300 DT on the roll bagmaking machine

Year: 1995

Продано

Comexi Nexus EVO solventless laminator

Year: 2005

Продано

W&H Primaflex flexo gearless printing press

Year: 2007

Продано

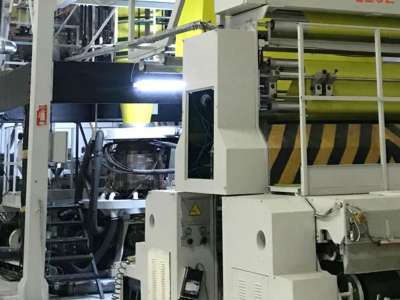

Reifenhauser blown film extrusion line

Year: 2010

Продано

Bielloni Telia flexo gearless printing press

Year: 2015

Продано

W&H Soloflex flexo CI printing press

Year: 1997

Продано

Comexi Dual combi laminator

Year: 2017

Продано

Alan Duffy ICS1000 slitter rewinder

Year: 1990

Продано

SML cast extrusion line

Year: 1997

Продано

H&S 1063W wicket bagmaking machine

Year: 1998

Продано

W&H Soloflex flexo CI printing press

Year: 2001

Продано

W&H Filmex cast extrusion line

Year: 2006

Продано

Bimec TCA slitter rewinder

Year: 2005

Продано

Nordmeccanica Simplex solventless laminator

Year: 2004

Продано

W&H Optimex blown film extrusion line

Year: 2011

Продано

Bimec STM slitter rewinder

Year: 2009

Продано

Coemter T-roll bag on the roll machine

Year: 1997

Продано

W&H Polyrex loophandle bagmaking machine

Year: 1997

Продано

Nordson SB2000 hotmelt coater

Year: 1995

Продано

LWKB Elb fa 1600 bottomseal bagmaking machine

Year: 1992

Продано

Bobst SL850 solventless laminator

Year: 2014

Продано

Jiajing JPW hydraulic baler

Year: 2018

Продано

Dolci cast extrusion line

Year: 2013

Продано

Colines cast extrusion line

Year: 2009

Продано

Jagerberg Vari Dur 33-18 slitter rewinder

Year: 1975

Продано

Remak MT6X1200 flexo CI printing press

YearL 2008

Продано

Soma Lamiflex solventless laminator

Year: 2010

Продано

Nordmeccanica Zenit solventbased laminator

Year: 1987

Продано

TItan SR7 slitter rewinder

Year: 2003

Продано

Schiavi Sigma flexo gearless printing press

Year: 2002

Продано

Titan SR8 slitter rewinder

Year: 2008

Продано

Rotomec wax coater

Year: 1976

Продано

Fas Flexuct Fasette C cutting unit

Year: 1998

Продано

W&H Novoflex flexo gearless printing press

Year: 2004

Продано

Sitec SMA 600/1300 slitter rewinder

Year: 1997

Продано

TCE cast extrusion line

Year: 2000

Продано

Reifenhauser blown film extrusion line

Year: 1985

Продано

Helmut Berger M139 die cutter

Year: 2004

Продано

BHS wax laminator/hotmelt coater

Year: 1985

Продано

Füll FS182 ink mixing installation

Year: 2001

Продано

Reifenhauser blown film extrusion line

Year: 1988

Продано

Rotomec Rotopak rotogravure printing press

YearL 1977

Продано

F&K 16S flexo gearless printing press

Year:2000

Продано

Dürr Ecopure RTO unit

Year: 1995

Продано

Kroenert Recco 800 triplex coater/laminator

Year: 2005

Продано

NGR S-Gran recycling line

Year: 2006

Продано

Alan Duffy Eagle DC 650 slitter rewinder

Year: 1989

Продано

Reifenhauser blown film extrusion line

YearL 1998

Продано

Schiavi Sigma4020 flexo printing press

Year: 2003

Продано

F&K 16S flexo gearless printing press

Year: 2000

Продано

W&H Soloflex flexo CI printing press

Year: 1988

Продано

Schiavi Alpha flexo gearless printing press

Year: 2002

Продано

Schiavi EF4040 flexo gearless printing press

Year: 2008

Продано

Uteco Coral flexo CI printing press

Year: 1994

Продано

Uteco Emerald flexo gearless printing press

Year: 2003

Продано

F&K 34DF flexo CI printing press

Year: 1995

Продано

Carint SLP flexo CI printing press

Year: 2005

Продано

Karlville KJ-SUP-400 pouch bagmaking machine

Year: 2017

Продано

Hemmingstone HM-1000MSR bag on the roll machine

Year: 2003

Продано

Hemmingstone HM-1000 drawtape bagmaking machine

Year: 2012

Продано

W&H Starflex flexo CI printing press

Year: 1997

Продано

Roll-o-Matic Delta 860 bagmaking machine

Year: 2008

Продано

W&H Starflex flexo CI printing press

Year: 1993

Продано

Arvor Eco Classic bottomseal bagmaking machine

Year: 2011

Продано

Tiquattro Elene flexo CI printing press

Year: 2004

Продано

Carint Gemini flexo CI printing press

YearL 1987

Продано

Ashe Sapphire S slitter rewinder

Year: 2006

Продано

Ashe Diamond slitter rewinder

Year: 2015

Продано

Wickeltechnick WFZ slitter rewinder

Year: 2000

Продано

Ashe Sapphire S slitter rewinder

Year: 2005

Продано

Uteco Mira solventless laminator

Year: 2015

Продано

Schiavi Ecoflex solventbased laminator

Year: 2010

Продано

Roll-o-Matic Delta 900 t-shirt bagmaking machine

Year: 2015

Продано

TMB Speedflex inline flexo printing press

Year: 2010

Продано

Schiavi Ecoflex solventless laminator

Year: 2000

Продано

Lemo Intermat wicket bagmaking machine

Year: 1994

Продано

Weyhmuller DSV70 ice cone wrap machine-1

Year: 2004

Продано

Soma Premia flexo gearless printing press

Year: 2014

Продано

Weyhmuller DSV70 ice cone wrap machine

Year: 2008

Продано

Uteco Emerald flexo gearless printing press

Year: 2010

Продано

Bimec STM-43 slitter rewinder

Year: 2012

Продано

Barmag blown film extrusion line

Year: 1996

Продано

Acom Variant 12 solventbased laminator

Year: 2004

Продано

Bimec STM-50 slitter rewinder

Year: 2016

Продано

Comexi FS-1500 flexo CI printing press

Year: 1996

Продано

Rotomec Valmet rotogravure printing press

Year: 2003

Продано

Polytype Bangerter alu coater

Year: 1970

Продано

Barmag blown film extrusion line

Year: 1989

Продано

Uteco Quartz inline flexo stack gearless printing press

Year: 2014

Продано

Olivini flexo gearless stack printing press

Year: 2001

Продано

Comexi S-Turret slitter rewinder

Year: 2013

Продано

Cerutti R940 rotogravure printing press

Year: 1997

Продано

Cobden Chadwick No2 paper bagmaking machine

Year: 1970

Продано

Megtec VOC RTO unit

Year: 2010

Продано

Macro Engineering blown film extrusion line

Year: 2013

Продано

Uteco Topax 608 flexo gearless printing press

Year: 2014

Продано

Andreotti Rotostar rotogravure printing press

Year: 1993

Продано

Nordmeccanica Super Simplex solventless laminator

Year: 1995

Продано

Bielloni B64 slitter rewinder

Year: 1990

Продано

Beasly&French No 2 paper bagmaking machine

Year: 1970

Продано

Kampf unwinders

Year: 1998

Продано

Beasly&French No 3 paper bagmaking machine

Year: 1970

Продано

Comexi S-Turret slitter rewinder

Year: 2013

Продано

W&H Varex blown film extrusion line

Year: 2008

Продано

Comexi SLC-120 solventless laminator

Year: 2001

Продано

Schiavi Padane wax coating line

Year: 2010

Продано

CMF Mirage flexo CI printing press

Year: 1988

Продано

H&S 2750W wicket bagmaking machine

Year: 1994

Продано

Eme Engel slitter rewinder

Year: 1995

Продано

Pratti Vegaplus label puncher

Year: 2014

Продано

Uteco Onyx flexo gearless printing press

Year: 2007

Продано

Raantec PlateExact 400 plate mounter

Year: 2013

Продано

Megtec CC60-C5 RTO unit

Year: 2009

Продано

Macchi blown film extrusion line

Year: 2006

Продано

Uteco Topaz 808 flexo gearless printing press

Year: 2012

Продано

Arvor Alpha 1499 bottomseal bagmaking machine

Year: 2002

Продано

Cerutti R38 rotogravure printing press

Year: 1976

Продано

Titan SR6 slitter rewinder

Year: 1995

Продано

F&K 34DF flexo CI printing press

Year: 1992

Продано

Atlas Copco GA26VSD compressor

Year: 2015

Продано

Schiavi Roto Cadet S rotogravure printing press

Year; 1995

Продано

Alphasonic ALP1630 ultrasonic anilox cleaner

Year: 2016

Продано

Uteco Rainbow solventless laminator

Year: 2012

Продано

Comexi Proslit Compack 2 slitter rewinder

Year: 2010

Продано

Lemo IV 1100 TU-ST diaper bagmaking machine

Year: 1999

Продано

CMR Flexporint 420-8GL flexo label printing press

Year: 2007

Продано

Sys Tec Star-HD sleeves 1300 plate mounter

Year: 2015

Продано

FAS CT500 cutting unit for T-shirt and top wave bags

Year: 2012

Продано

Uteco Zeus 188 slitter rewinder

Year: 2012

Продано

Polytype KST6630 solventless laminator

Year: 1994

Продано

MAM blown film extrusion line

Year: 1997

Продано

Sys Tec VP-HD 1200 plate mounter

Year: 2011

Продано

Sitec SMA 600/1300 slitter rewinder

Year: 1996

Продано

FAS CT500 cutting unit for T-shirt and top wave bags

Year: 2012

Продано

Hobema 14C napkin machine

Year: 1976

Продано

Nilpeter 2400 flexo label printing press

Year: 1999

Продано

Rotomec 3000-3R rotogravure printing press

Year: 1998

Продано

W&H Triumph 5 paper bagmaking machine

Year: 1972>

Продано

Flexotecnica Tachys flexo CI printing press

Year: 1998

Продано

Comexi FI flexo gearless printing press

Year: 2006

Продано

W&H Miraflex flexo gearless printing press

Year: 2011

Продано

W&H Primaflex flexo gearless printing press

Year: 2006

Продано

Comexi FW flexo gearless printing press

Year: 2009

Продано

W&H Stellaflex flexo CI printing press

Year: 1996

Продано

W&H Stellaflex flexo CI printing press

Year: 1996

Продано

W&H Astraflex flexo CI printing press

Year: 2000

Продано

W&H Soloflex flexo CI printing press

Year: 1995

Продано

Bobst 20six flexo gearless printing press-1

Year: 2015

Продано

W&H Miraflex flexo gearless printing press

Year: 2015

Продано

Comexi FW flexo gearless printing press

Year: 2002

Продано

Comexi FL flexo gearless printing press

Year: 2003

Продано

Ofem Appia GL808 flexo gearless printing press

Year: 2007

Продано

Somo Midi II flexo gearless printing press

YearL 2011

Продано

BHS Flexoline Vario flexo gearless printing press

Year: 2003

Продано

Flexotecnica Policroma flexo CI printing press

Year: 2007

Продано

Lemo Capmat 850 courier bagmaking machine

Year: 2012

Продано

F&K 16S flexo gearless printing press

Year: 2001

Продано

Flexotecnica Chronos flexo gearless printing press

Year: 2004

Продано

Lemo 850DKT patch handle bagmaking machine

Year: 1999

Продано

W&H Polyrex loophandle bagmaking machine

Year: 2002

Продано

Flexotecnica 806 flexo CI printing press

Year: 1984

Продано

Lemo Intermat wicket bagmaking machine

Year: 1994

Продано

Comexi FW flexo gearless printing press

Year: 2011

Продано

W&H Stellaflex flexo CI printing press

Year: 1997

Продано

Flexotecnica FX8 waterbased flexo gearless printing press

Year: 2010

Продано

Avita AVP courier bagmaking machine

Year: 2013

Продано

W&H Starflex flexo CI printing press

Year: 1993

Продано

FMC 105 courier bagmaking machine

Year: 2010

Продано

Bone Craven blown film extrusion line

Year: 1974

Продано

W&H Starflex flexo CI printing press

Year: 1994

Продано

Uteco Onyx flexo gearless printing press

Year: 2012

Продано

W&H Matador 26 paper bagmaking machine

Year: 1975

Продано

Comexi FP flexo CI printing press

Year: 1997

Продано

Stiegler wicket bagmaking machine

Year: 2000

Продано

Bobst Rotoextruder 700 extrusion laminating line

Year: 2015

Продано

Comexi FW flexo gearless printing press

Year: 2004

Продано

Bielloni Taglierina slitter rewinder

Year: 2007

Продано

F&K vulcanising unit

Year: 1962

Продано

Uteco-Usimeca LMA slitter rewinder

Year: 1995

Продано

Reifenhauser blown film extrusion line

Year: 1992

Продано

F&K 16S flexo gearless printing press

Year: 2002

Продано

W&H Primaflex flexo gearless printing press

Year: 2005

Продано

Cerutti R940 rotogravure printing press

Year: 2002

Продано

Lemo bottomseal bagmaking machine

Year: 2016

Продано

Reifenhauser blown film extrusion line

Year: 1999

Продано

Soma Z3540C slitter rewinder

Year: 2000

Продано

Polytype wax coating line

Year: 1970

Продано

Leybold lab high vacuum coater

Year: 2007

Продано

Reifenhauser blown film extrusion line

Year: 1991

Продано

Kampf FK2-2 slitter rewinder

Year: 1965

Продано

Bobst 20six waterbased flexo gearless printing press

Year: 2012

Продано

H&S 5750W wicket bagmaking machine

Year: 2010

Продано

Nordmeccanica Triplex SL One Shot solventless laminator

Year: 2009

Продано

Z-rite Exact Spectrometer

Year: 2014

Продано

OMM AZ2 UT 3000 wide web slitter rewinder

Year: 1988

Продано

Nordmeccanica Super Simplex solventless laminator

Year: 2002

Продано

Harro Höfliger medical bagmaking machine

Year: 2013

Продано

Nordmeccanica Zenit solventbased laminator

Year: 1988

Продано

AV Flexologic plate mounter

Year: 1995

Продано

Waterline pouch bagmaking machine

Year: 1996

Продано

Reifenhauser blown film extrusion line

Year: 1983

Продано

Uteco SH 350 rotogravure printing press

Year: 2014

Продано

Titan SR6 slitter rewinder

Year: 1996

Продано

Comet S674 blown film extrusion line

Year: 2000

Продано

Comexi Proslit Duo 2 slitter rewinder

Year: 2007

Продано

Comexi Dual combi laminator

Year: 2011

Продано

Cerutti R940 rotogravure printing press

Year: 1997

Продано

Vela RB-600 sleeve maker

Year: 2007

Продано

Elba BM11BW13 bottomseal bagmaking machine

Year: 2015

Продано

Comet S674 blown film extrusion line

Year: 2005

Продано

Nordmeccanica Super Combi laminator

Year: 2005

Продано

Polymount L-2 plate cleaner

Year: 2012

Продано

W&H Astraflex flexo CI printing press

Year: 2001

Продано

W&H solventless laminator

Year: 1991

Продано

Comet S674 blown film extrusion line

Year: 1998

Продано

Eme FXCM flexo stack printing press

Year: 1998

Продано

Renzmann anilox washing machine

Year: 2007

Продано

Euromac TB-510 slitter rewinder

Year: 1986

Продано

BHS FS-650 flexo label printing press

Year: 1999

Продано

Lemo Intermat 1100 hygiene bagmaking machine

Year: 1994

Продано

Erema 756 TE-SW recycling line

Year: 2008

Продано

Flexowash SL6 sleeve washer

Year: 2009

Продано

Nilpeter FA4 flexo label printing press

Year: 2007

Продано

Bieffebi Mirage 336-180C plate mounter

Year: 1996

Продано

Comet S674 blown film extrusion line

Year: 1992

Продано

Euromac TB-506 slitter rewinder

Year: 1999

Продано

Renzmann Roto-400 destillation unit

Year: 2004

Продано

Schiavi Eco Convert solventless laminator

Year: 1998

Продано

Flexotecnica Ekaton inline flexo stack printing press

Year: 1990

Продано

W&H Novoflex XS flexo gearless printing press

Year: 2005

Продано

W&H Soloflex flexo CI printing press

Year: 1994

Продано

Comexi FPLUS flexo gearless printing press

Year: 2012

Продано

PCMC Infiniti flexo gearless printing press

Year: 2000

Продано

W&H Soloflex flexo CI printing press

Year: 2004

Продано

W&H Soloflex flexo CI printing press

Year: 2002

Продано

F&K 31DF flexo stack printing press

Year: 1971

Продано

F&K 34DF flexo CI printing press

Year: 1990

Продано

W&H Novoflex flexo gearless printing press

Year: 2000

Продано

W&H QMS flexo stack printing press

Year: 1970

Продано

Eme FXCM flexo stack printing press

Year: 2002

Продано

Comexi FP flexo CI printing press

Year: 2000

Продано

Comexi FX flexo CI printing press

Year: 1996

Продано

Comexi FB flexo gearless printing press

Year: 2004

Продано

W&H Soloflex flexo CI printing press

Year: 1999

Продано

Bonardi Ofelia flexo stack printing press

Year: 2003

Продано

W&H TR1 SOS paper bagmaking machine

Year: 1972

Продано

Coemter Ter Roll bag on the roll machine

Year: 1998

Продано

GN 26P security pouch bagmaking machine

Year: 2003

Продано

Lee Yuen inline flexo stack printing press

Year: 2013

Продано

Hettler FK2000 cottonstring bagmaking machine

Year: 2010

Продано

Some Mini 8 flexo gearless printing press

Year: 2006

Продано

Totani BH-60V pouch bagmaking machine

Year: 1999

Продано

Lemo Intermat wicket bagmaking machine

Year: 2000

Продано

F&K 16S flexo gearless printing press

Year: 2001

Продано

Flexotecnica 10NG flexo gearless printing press

Year: 2009

Продано

FMC 2750W wicket bagmaking machine

Year: 1992

Продано

Totani BH-600 BL pouch bagmaking machine

Year: 1986

Продано

Lemo Varitronic 1100 drawtape bagmaking machine

Year: 1999

Продано

MAF Galaxi flexo CI printing press

Year: 1993

Продано

Euroexma lab blown film extrusion line

Year: 2015

Продано

MAF Galaxi flexo CI printing press

Year: 1989

Продано

W&H AD Convertex blockbottom/valve bagmaking machine

Year: 2000

Продано

Lemo S850 glue patch bagmaking machine

Year: 2002

Продано

W&H Olympia 900 flexo stack printing press

Year: 1977

Продано

Roll-o-Matic 605 t-shirt bagmaking machine

Year: 2002

Продано

W&H Filmex cast extrusion line

Year: 2011

Продано

Rotomec extrusion laminating line

Year: 1975

Продано

W&H Varex blown film extrusion line

Year: 1998

Продано

Chadwick flexo CI printing press

Year: 1988

Продано

Waterline Ritebag 600 pouch bagmaking machine

Year: 2013

Продано

Lemo drawtape bagmaking machine

Year: 2002

Продано

F&K 34DF flexo CI printing press

Year: 2000

Продано

Formac Mini 20 lab blown film extrusion line

Year: 1999

Продано

Yei blown film extrusion line

Year: 1998

Продано

De Bernardi 100E pouch bagmaking machine

Year: 2003

Продано

Uteco Onyx 876 flexo gearless printing press

Year: 2005

Продано

W&H Rotalux bottomseal bagmaking machine

Year: 1989

Продано

Carint Cyberflex flexo gearless printing press

Year: 2004

Продано

Yei blown film extrusion line

Year: 2000

Продано

F&K 10DF flexo CI printing press

Year: 1996

Продано

Gunter bottomseal bagmaking machine

Year: 2002

Продано

Curioni Sun 540 paper bagmaking machine

Year: 1998

Продано

Reifenhauser blown film extrusion line

Year: 2001

Продано

Fin Kon wicket bagmaking machine

Year: 1998

Продано

Bielloni Theorema flexo gearless printing press

Year: 2003

Продано

Reifenhauser blown film extrusion line

Year: 2001

Продано

W&H AMD flexo inline stack printing press

Year: :1975

Продано

Holweg RS26 paper bagmaking machine

Year: 1997

Продано

W&H Olympia 850 flexo stack printing press

Year: 1980

Продано

Reifenhauser blown film extrusion line

Year: 2001

Продано

Coemter Ter Roll bag on the roll machine

Year: 1999

Продано

W&H Convertronic pouch bagmaking machine

Year: 1995

Продано

Schiavi Sirio flexo CI printing press

Year: 2001

Продано

Flexotecnica flexo CI printing press

Year: 1996

Продано

F&K 34DF flexo CI printing press

Year: 1982

Продано

Alpine blown film extrusion line

Year: 1993

Продано

Ashe Solitaire slitter rewinder

Year: 2007

Продано

Carint Skorpion flexo CI printing press

Year: 2011

Продано

Ashe Solitaire slitter rewinder

Year: 2002

Продано

Erwepa cast extrusion line

Year: 2000

Продано

Metecor flexo stack printing press

Year: 2005

Продано

Ahlstrom Syromat jumbo slitter rewinder

Year: 1990

Продано

Renova cottonstring bagmaking machine

Year: 1997

Продано

Macchi blown film extrusion line

Year: 2002

Продано

Coemter t-shirt bagmaking machine

Year: 1994

Продано

Galileo MSR25 slitter rewinder

Year: 2003

Продано

Hanyoung extrusion coating line

Year: 2001

Продано

W&H Olympia 746 flexo CI printing press

Year: 1989

Продано

PSA Allslit slitter rewinder

Year: 2009

Продано

Wolf sheeter with inline printing unit

Year: 1980

Продано

Hanyoung extrusion coating line

Year: 2001

Продано

W&H Starflex flexo CI printing press

Year: 1992

Продано

W&H Matador S1 paper bagmaking machine

Year: 1996

Продано

Lemo Rollomat bag on the roll bagmaking machine

Year: 1996

Продано

Addex blown film extrusion line

Year: 2004

Продано

Carint Gemini flexo CI printing press

Year: 1991

Продано

Nordmeccanica Super Combi laminator

Year: 2014

Продано

Comexi Nexus Dual combi laminator

Year: 2008

Продано

H&S 4750W wicket bagmaking machine

Year: 2001

Продано

Macchi blown film extrusion line

Year: 1996

Продано

Kampf Conslit 10/60 slitter rewinder

Year: 1996

Продано

Flexotecnica NG8 flexo gearless printing press

Year: 2009

Продано

Galileo Mega 2410A metalizer

Year: 1998

Продано

BAT hydraulic compactors

Year: 2003

Продано

W&H Olympia flexo CI printing press

YearL 1980

Продано

Lemo Intermat bottomseal bagmaking machine

Year: 1986

Продано

Mix Master ink blending system

Year: 2001

Продано

H&S MS1000 sideseal bagmaking machine

Year: 2002

Продано

Pro Doing slitter rewinder

Year: 2005

Продано

Fong Kee cast extrusion line

Year: 2002

Продано

Flexowash FW3000 anilox cleaner

Year: 2003

Продано

Ofem Selenia solventless laminator

Year: 2002

Продано

Bielloni Gloria flexo CI printing press

Year: 1996

Продано

H&S MS750 sideseal bagmaking machine

Year: 2005

Продано

Delta Graphic slitter rewinder

Year: 1998

Продано

Imaje Jaime 1000 inkjet printers

Year: 2006

Продано

Reifenhauser blown film extrusion line

Year: 1996

Продано

W&H Soloflex flexo CI printing press

Year: 1998

Продано

Pagendarm Lamicoater

Year: 1984

Продано

Arvor unwinder

Year: 1997

Продано

W&H Soloflex flexo CI printing press

Year: 1999

Продано

Uteco-Usimeca slitter rewinder

Year: 1996

Продано

Lemo Intermat loophandle bagmaking machine

Year: 2004

Продано

Comexi CL 1300 solventless laminator

Year: 2002

Продано

NM PA-100 automatic core cutter

Year: 1999

Продано

FAS UWB unwinder

Year: 2006

Продано

F&K 14DF flexo CI printing press

Year: 1983

Продано

Holweg Multiplex combi laminator

Year: 1976

Продано

Lemo Intermat wicket bagmaking machine

Year: 1995

Продано

Titan slitter rewinder

Year: 1999

Продано

Holweg sheeter

Year: 1985

Продано

Barmag monofilament extrusion line

Year: 2008

Продано

SVT drawtape unit

Year: 2007

Продано

Fimap ultrasonic anilox cleaner

Year: 2003

Продано

Comexi FP flexo CI printing press

Year: 1998

Продано

Colombo M139 embosser

Year: 2005

Продано

Cerutti R940 rotogravure printing press

Year: 1993

Продано

Schiavi Easy slit slitter rewinder

Year: 1998

Продано

Lemo Intermat DKT bagmaking machine

Year; 1999

Продано

W&H Stellaflex flexo CI printing press

Year: 1997

Продано

Spag BAC800 slitter rewinder

Year: :1996

Продано

Black Clawson cast extrusion line

Year: 1998

Продано

Schiavi Eco Convert Junior solventless laminator

Year; 1998

Продано

Rotomec Rotopak rotogravure printing press

Year: 1989

Продано

Schiavi Eco Convert Junior solventless laminator

Year: 2002

Продано

Wolf sheeter

Year: 1985

Продано

W&H Stellaflex flexo CI printing press

Year: 1997

Продано

Saldoflex t-shirt bagmaking machine

Year: 2008

Продано

Bimec SMT slitter rewinder

Year: 2009

Продано

Renzmann Roto-140 destillation unit

Year: 2000

Продано

Stiegler wicket bagmaking machine

Year: 2000

Продано

Colines cast extrusion line

Year: 1994

Продано

Manzoni flexo stack printing press

Year: 1998

Продано

Polytech rotogravure printing press

Year: 2004

Продано

W&H Starflex flexo CI printing press

Year: 1990

Продано

Solutex destillation unit

Year: 2009

Продано

Reeco-Stroem after burner

Year: 1997

Продано

Dolci blown film extrusion line

Year: 2004

Продано

Comexi Proslit slitter rewinder

Year: 2008

Продано

Andriotti Rotostar solventbased laminator

Year: 1985

Продано

Erwepa extrusion laminating/coating line

Year: 2012

Продано

Cerutti 18R rotogravure printing press

Year: 1975

Продано

Plast-control K400U air ring

Year: 2006

Продано

Elwa bottomseal bagmaking machine

Year: 1993

Продано

General EHF4 metalizer

Year: 2000

Продано

Engin Plast trim granulator

Year: 1995

Продано

Flexotecnica Prisma flexo CI printing press

Year: 1998

Продано

Schiavi Easy Slit slitter rewinder

Year: 1988

Продано

W&H Heliostar coater

Year: 1995

Продано

Dolci blown film extrusion line

Year: 1980

Продано

Cerutti rotogravure printing press

Year: 1989

Продано

Nishibe SBM-600 pouch bagmaking machine

Year: 2005

Продано

Nordmeccanica Simplex combi laminator

Year: 1996

Продано

Bieffebi Omnia 335 plate mounter

Year: 2006

Продано

Horstmann roll carts for recycling lines

Year: 2000

Продано

Renzmann DW100 destillation unit

Year: 1997

Продано

Fong Kee cast extrusion line

Year: 1998

Продано

W&H Rotiflex flexo/roto printing press

Year: 1974

Продано

Stiegler drawtape bagmaking machine

Year: 1999

Продано

Lombardi Lexus 450 flexo label printing press

Year: 2010

Продано

SRS 410 slitter rewinder

Year: 2015

Продано

Rotogravure cylinders

Year: 1990

Продано

CDM ES50 recycling line

Year: 2006

Продано

Giave Titania rotogravure printing press

Year: 1994

Продано

Printex bottomseal bagmaking machine

Year: 1974

Продано

Heaford Cobra plate mounter

Year: 2012

Продано

Schiavi Polaris flexo CI printing press

Year: 1998

Продано

Cosmoplastik solventbased laminator

Year: 1994

Продано

Flexo Wash TK200WR parts washer-1

Year: 2005

Продано

Uteco-Usimeca LMA slitter rewinder

Year: 1995

Продано

Omet flexo label printing press

Year: 2009

Продано

Rotomec Valmet rotogravure printing press

Year: 1998

Продано

Macchi blown film extrusion line

Year: 2002

Продано

Bobst 20six flexo gearless printing press

Year: 2013

Продано

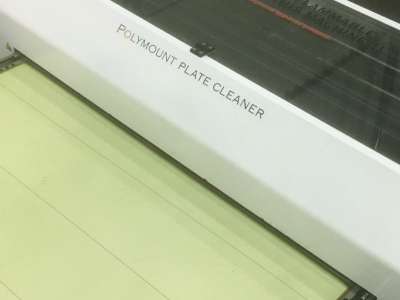

Polymount plate cleaner

Year: 2008

Продано

DCM Laminawax wax coater/laminator

Year: 2007

Продано

Flexo Wash TK200WR parts washer

Year: 2002

Продано

Munchy P100 recycling line

YearL 1994

Продано

Kiefel blown film extrusion line

Year: 2006

Продано

Entry tight 660 solventless laminator

Year: 2008

Продано

Dolci cast extrusion line

Year: 1993

Продано

AGFA Avantra image setter

Year: 1999

Продано

Uteco-Usimeca DAB slitter rewinder

Year: 1999

Продано

BHS flexo label printing press

Year: 1983

Продано

Starlinger Recostar 125 recycling line

Year: 2004

Продано

Cerutti rotogravure printing press

Year: 1971