| Machine manufacturer | Macchi |

| Year | 2004 |

| Layers | 3 |

| Diameter screw(s) | 50 - 80 - 55 |

| L:D ratio screw(s) | 30D - 25D - 30D |

| Diameter die | 350 mm |

| Max. web width | 1650 mm |

| Max. output | 350kg/h |

| Type of winding | Double for flat film |

| Materials |

LDPE, LLDPE, BLENDS HDPE, MDPE, mLLDPE 20 – 200 micron |

| Max. rewind reel diameter | 850 mm |

| Type of dosing unit | Gravimetric, Doteco |

| IBC | Yes |

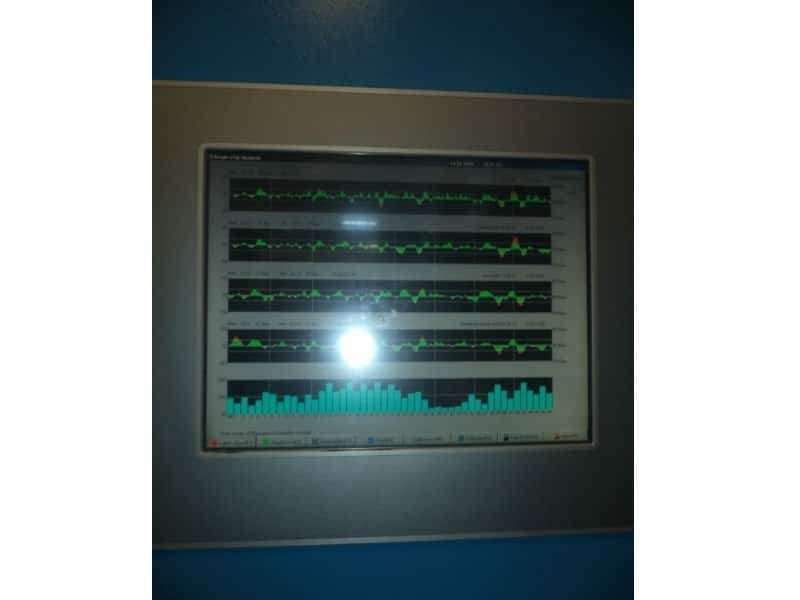

| Thickness measurement | Yes, Kundig |

| Web guide(s) | Yes, E&L |

| Corona treater | Yes, 2 sides, Ferrari & Benelli |

| Inline slitting | Yes |

| Tower construction included | Yes |

| Available from | Now |

| Machine can be seen in production | Yes |

Used Macchi extruder line. This is a 3 layer blown film extrusion line which is in very good condition. Machine is produced in 2004 but very well maintained and still daily producing. It has a back to back winder and is equipped with a lot of options such as corona, gravimetric dosing unit, thickness measurement and IBC. Availalbe directly and can be seen in production.